This machine shapes the shoe upper by heating it with the upper mold to soften the material. Simultaneously, using the silicone heat-resistant soft rubber mold of the lower mold under specific pressure and temperature conditions, the upper is formed to match the shape of the shoe last, achieving the shaping effect.

The upper mold can rapidly heat up and dissipate heat evenly, with the temperature of the outer aluminum mold reaching up to 200°C.

The lower mold is a silicone heat-resistant soft rubber mold integrated with an inflatable inner bladder. Its position can be adjusted front-to-back to better adapt to the shaping requirements of different shoe types.

Composed of temperature sensors, a controller, heating elements, etc., it enables precise control of the upper mold’s heating temperature, ensuring the upper is shaped at an optimal temperature. The upper mold temperature can be freely adjusted between 50°C and 200°C according to the heat resistance of different upper materials.

Equipped with devices such as pressure gauges to adjust the air bladder pressure and secondary pressing pressure. Through precise pressure control, the upper receives uniform pressure during shaping, guaranteeing consistent shaping results.

| Technical Specifications: |

| Model | Voltage | Power | Capacity | NW | Machine Size |

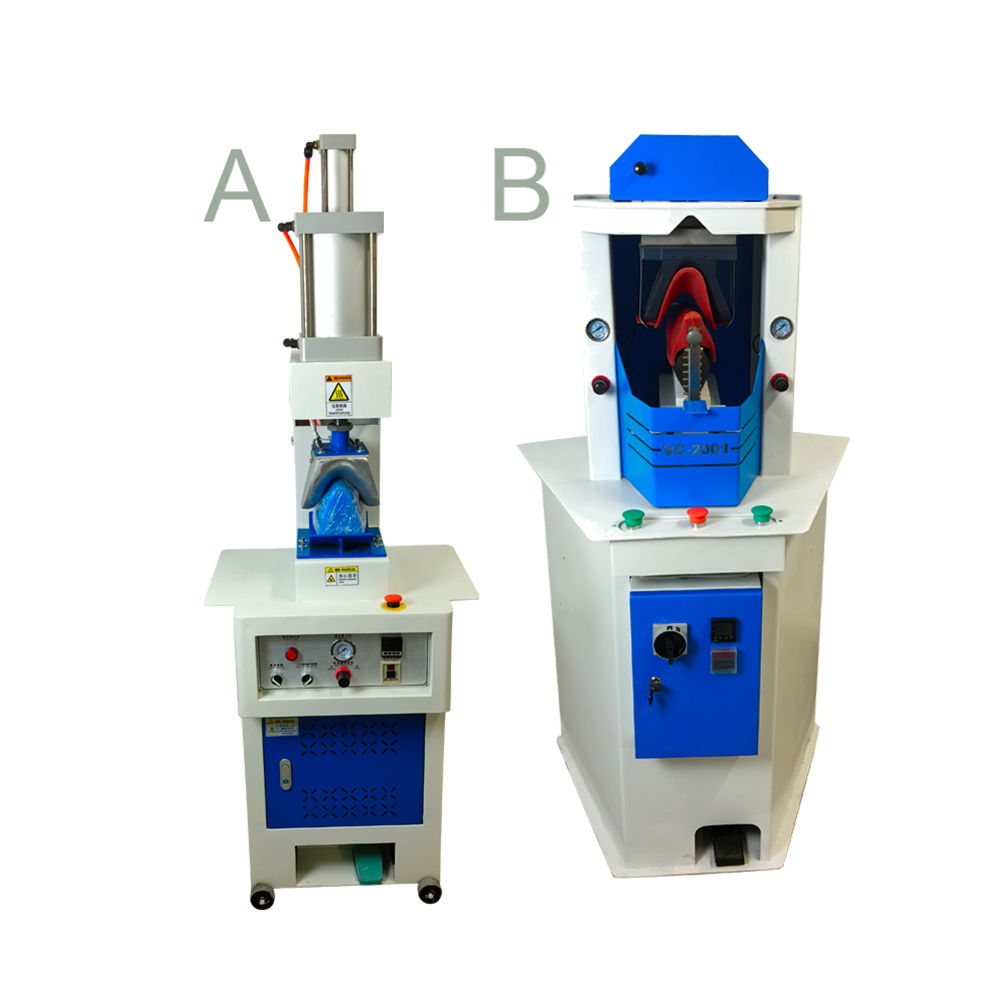

| SC-326A | 220V | 0.5KW | 800airs/8th | 80KG | 550*550*1850MM |

| SC-326B | 220V | 1KW | 1200airs/8th | 150KG | 800*550*1850MM |

Ulasan

Belum ada ulasan.